PROCESS

The success of Raytech’s multidisciplinary qualitative research and product development process begins with an identified need, and is driven by our success in developing a relationship between end users and clients’ brands and products. As a product research and development consulting firm, Raytech develops design solutions based on our clients’ business strengths, through the use of discovery, innovation and product engineering.

Beginning with the establishment of critical deliverables, the understanding of market factors, and perceptions of users’ expectations and product requirements, our design team develops product solutions based on our four-stage process:

INVESTIGATE - INNOVATE - VALIDATE - IMPLEMENT

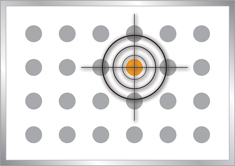

INVESTIGATE

Our design and user research team captures feedback from stakeholders and establishes the foundation for the product development process. This preliminary discovery process is designed to capture feedback about the new product from stakeholders and establish the foundation for the product development process.

Research methods and tools are implemented based on factors such as clients’ business goals, market access, and product history. This first stage study includes a matrix for reference and guidance during the product design and product engineering processes.

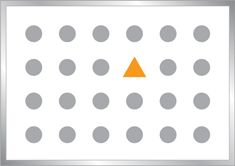

INNOVATE

With a fundamental understanding of users in the target market, our product design team creates innovative concepts driven by, and tied to, research discoveries. Innovation is most valuable for our clients when it is tied to actionable methods and decisions.

The product design team at Raytech provides product concepts which are then further developed and evaluated by the client and market stakeholders. This iterative development and review process provides opportunity to validate concepts before the design is detailed for manufacturing.

VALIDATE

Product validation is performed using physical mock-ups, 3D CAD renderings, mock-interface models, process and task assessment diagrams, and storyboarding.

Concept prototypes and functional interfaces are analyzed for functionality, human factors issues, and market buy-in. This evaluation process is a conduit for the development team to interface with our client’s stakeholders, helping clients confirm which product goals have been achieved, and what improvements are desirable.

This third stage of the process provides opportunity for the team to verify that the intended functionality meets the necessary product specifications and requirements and end-users expectations.

Additional validation methods include material selection, mold flow analysis, and finite element analysis (FEA). With the confirmation of form, function, product messaging, materials and strength, the product solution is ready to progress Implementation.

IMPLEMENT